Who makes car wash equipment?

Trying to find a reliable manufacturer for car wash tools? It's a specialized world, often hidden from plain sight. The truth is, the real experts are concentrated in specific hubs.

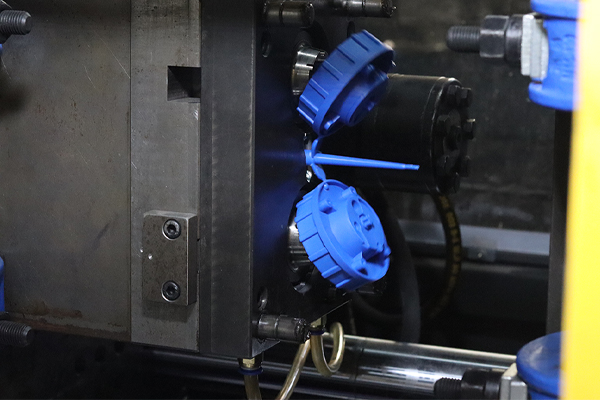

The vast majority of car wash equipment1 is made by specialized manufacturers2 in China. Cities like Yuhuan and Taizhou3 in the Zhejiang province4 are global hubs, possessing the complete industrial supply chain5 from mold making6 and injection molding7 to CNC machining8, creating a one-stop-shop for production.

<sup id=](https://flowstools.com/wp-content/uploads/2025/10/%E5%B7%A5%E5%8E%82-1.jpg)

Why is it so hard to find dedicated car wash equipment1 factories?

Searching for a factory can feel frustrating. You find general manufacturers, but few true specialists. Is this industry just too small or is there another reason for this?

The car wash equipment industry is a niche category, so it's not widely known. However, it's an essential market. Because manufacturing requires a highly integrated supply chain—from molds to metal parts—factories are concentrated in specific industrial zones rather than being widespread, making them harder to find individually.

Where is the global hub for car wash equipment manufacturing?

You want to find the source. If one place has everything needed, where is it? Knowing this can save you time and connect you with the most capable partners.

The undisputed global hub is China's Zhejiang province, specifically the cities of Yuhuan and Taizhou3. This area contains every part of the production chain, from advanced mold-making and massive injection molding7 industries to world-class CNC machining8 for metal parts. It's truly a one-stop solution.

What does the car wash equipment1 supply chain11 actually look like?

You hear about supply chains, but what do they really involve? Understanding the specific steps and where they happen shows you why a product's origin is so important for quality.

The supply chain starts with precision mold making6. It then moves to high-volume plastic injection molding7 for the body, and CNC machining8 for metal parts. Finally, processes like electroplating12 add durability. Each step is a specialized industry, all located together in Zhejiang.

The Key Pillars of Production

- Mold Making: Everything starts with a mold. This is the most critical and high-tech step. The precision of the mold determines the quality of the final product. The best mold makers are concentrated in Guangdong and Zhejiang.

- Injection Molding: Once the mold is ready, we need to create the plastic parts. Taizhou is a pillar of China's injection molding industry. They can produce anything from simple bottles to complex housings for our tools.

- CNC Machining: For any metal parts like nozzles, connectors, or internal valves, we need precision machining. Yuhuan's expertise in valve production means it's saturated with advanced CNC workshops, ensuring every metal component is perfect.

- Accessory Processes: This includes things like electroplating for metal parts to prevent rust and give a professional finish. These supporting factories are essential and surround the primary manufacturers.

| Process Stage | Core Industry | Main Location | Role in Car Wash Equipment |

|---|---|---|---|

| 1. Design | Mold Making | Guangdong, Zhejiang | Creates the high-precision steel molds |

| 2. Body | Injection Molding | Taizhou, Zhejiang | Forms the plastic bodies and handles |

| 3. Components | CNC Machining | Yuhuan, Zhejiang | Machines durable metal nozzles & connectors |

| 4. Finishing | Electroplating & Assembly | Zhejiang | Adds protective coatings and assembles parts |

This integration is why Zhejiang is the ultimate destination for anyone serious about developing or sourcing car wash equipment.

Conclusion

To find the best car wash equipment makers, look to Yuhuan, China. This is where the complete, mature supply chain for manufacturing high-quality cleaning tools is located.

Explore this link to discover top manufacturers and their offerings in the car wash equipment industry. ↩

Learn about the key players in the specialized manufacturing of car wash tools and their unique capabilities. ↩

Discover the significance of Yuhuan and Taizhou in the car wash equipment sector and their manufacturing strengths. ↩

Find out why Zhejiang province is a critical hub for manufacturing and how it impacts various industries. ↩

Understand the components of an industrial supply chain and its importance in manufacturing efficiency. ↩

Discover the critical steps involved in mold making and its importance in product development. ↩

Learn about the injection molding process and its significance in producing high-quality plastic parts. ↩

Explore the role of CNC machining in manufacturing and its impact on product quality. ↩

Explore the concept of a manufacturing ecosystem and its role in successful production. ↩

Learn about the unique challenges faced by the car wash sector and how they impact the industry. ↩

Get insights into the structure of a supply chain and how it affects manufacturing operations. ↩

Find out how electroplating enhances product durability and finish in manufacturing. ↩